Have any questions?

+44 1234 567 890

DVC

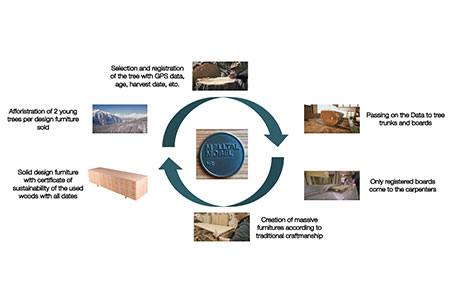

Digitization of a value chain from a tree to a furniture

6 joineries and a sawmill from the Mölltal / Carinthia with more than 100 employees are combined on an IoT compliant platform for the production of designer furniture. This design furniture will be distributed on the international market. The entire value chain - from the grown tree to the delivery of the piece of furniture – will be digitized. Every piece of furniture can be traced back to its tree. When placing an order, a customer receives the access code for an app with which he can retrieve all the data of his piece of furniture as well as the status in production; E.g.: Video of the tree during the hitting, GPS data of the tree, date and moon phase of the hitting, age of the tree, videos incl. live camera from the production, etc. ADH Mölltal Möbel GmbH, a startup from Carinthia, takes care of the development of the platform, its operation and the digitization of the entire value chain. LaserIDENT Systems GmbH is working on a method of identifying trees and on the inheritance of the ID of trees to their boards.

Project type

Prototype

Project budget

(IoT4industry funding): 90 000 €

Project end date

(estimated): March 2020

Solutions

A handheld with installed software that creates a connection to a so-called material database in the cloud has to be used by the forester as well as the sawmill workers during the timber harvest and further processing in the sawmill.

The identification takes place via two-dimensional bar-codes, which are scanned by the handheld according to the instructions of the installed APP. The scanned codes are then linked by the software so that a single wooden board could be traced back to its tree trunk and to its tree stump. All data, including the GPS data of the tree stump, the harvest date of the tree, etc., is synchronized with the material database.

The backbone of the sales and production process is an IoT system that controls the corresponding digitized processes. The material database, vendors, manufacturers and customers are integrated into these digitized processes.

The customer is able to follow via an APP every single step of the furniture's manufacturing he receives, when ordering his furniture.

This project was only made possible by the EU funding "IoT4Industrie".

Quote

Ing. Rindlisbacher Kurt, managing director, (https://www.rindlisbacher.at): "With TimberIdent our handicraft was strongly revalued. And we have the possibility to communicate automatically and directly with the customer via the digitalized processes".

Klaus Reiter, CEO Timberra, (https://www.timberra.com/shop/): "With TimberIdent, we have significantly upgraded our craft: "TimberIdent gives us the opportunity to transparently show our customers the origin and sustainability of the wood we use. This offers us a wealth of new marketing opportunities."

Contact Details

ADH Mölltal Möbel GmbH

Peter Lindner

Döllach 123

9843 Großkirchheim

Mobil:+43 699 11116166

Homepage: https://www.mdm-arts.at

Project Description: https://www.mdm-arts.at/die-digitalisierung-der-wertschopfungskette-vom-gewachsenen-baum-bis-zum-fertigen-mobelstuck/

Firmenbuch: FN 502461p

ATU 74111025

Partners involved

| Logo / Website | Name | Type | Country | Region |

|---|---|---|---|---|

|

ADH Mölltal Möbel | SME | Austria | NUTS Region „Oberkärnten“ |

|

LaserIDENT Systems | SME | Germany | NUTS Region „Darmstadt“ DE712 |

Vertical sector addressed

- Furnitures

Industrial application addressed

- Track & trace

- Monitoring & control

Technologies involved

- IoT & wearables