Have any questions?

+44 1234 567 890

EASYDIAG

Easy and low-cost Machine diagnostic

We know that existing industries must be more efficient to be more competitive and especially in European countries. One way to ramp up the efficiency is to decrease the non-provisional failure of machine to avoid stop of manufacturing. The difficulty of this market is the cost to install a predictive maintenance and the difficulty to install it. The “Grail” is to predict and explain which components of a machine and when exactly the failure will occur. This is not the aim of this project. The project aims to develop a simple system indicating that the energy consumption and the temperature variations are abnormal or unusual so that the person in charge of the maintenance intervenes to examine the machine. The objective is to give a first level of warning to the maintenance manager. GULPLUG conceived innovative non-intrusive and autonomous sensors for energy monitoring and Schneider Electric develop an innovative temperature sensor. GULPLUG develops in collaboration with Probayes specific algorithms to provide maintenance services. The solution is tested on machines in a Schneider Electric factory in Stezzano, Italy.

Project type

Prototype

Project budget

(IoT4industry funding): 45 000 €

Project end date

(estimated): March 2020

Solutions

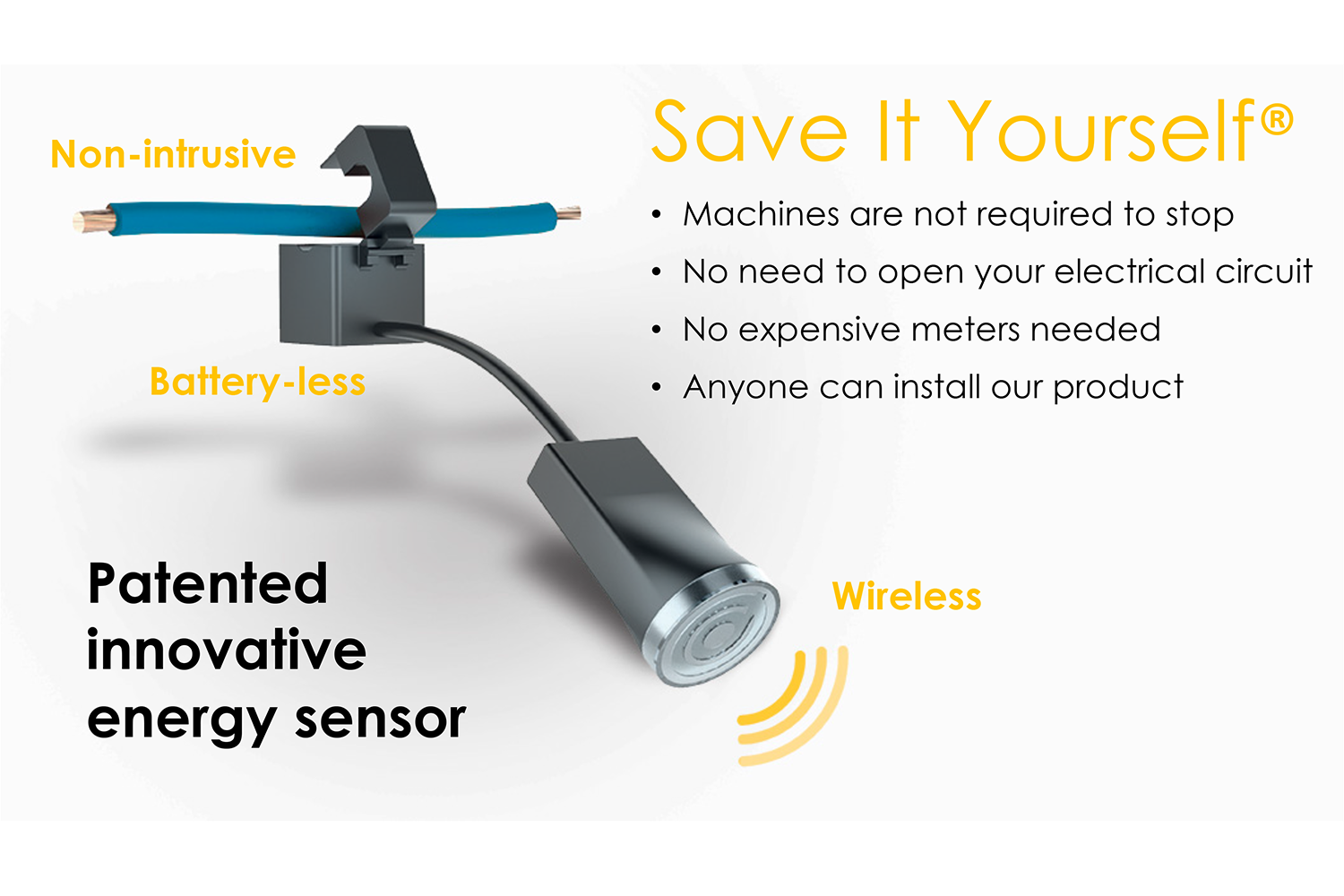

The solution proposed by Gulplug is based on sensors developed to monitor electrical energy and on sensors to monitor temperature variation. These sensors are autonomous, non-intrusive and easy to install. The main advantage to use these sensors is the shared network already developed for energy management. The infrastructure (sensors, local network, cloud network, HMI) is mutualised and cost effective. The energy sensor continually harvests a small part of inductive energy on the machine cable to power the electronic and send the signal by radio. This is also the way to measure the consumption of the machine.

Partners involved

| Logo / Website | Name | Type | Country | Region |

|---|---|---|---|---|

|

GULPLUG | SME | France | Auvergne-Rhône Alpes |

|

Schneider Electric | Large company | Italy | Nord-Est |

|

PROBAYES | SME | France | Auvergne-Rhône Alpes |

Vertical sector addressed

- Electronics

Industrial application addressed

- Predictive maintenance

Technologies involved

- IoT