Have any questions?

+44 1234 567 890

iPlanner

Optimization of manufacturing resources with a Discrete Event Simulator based solution

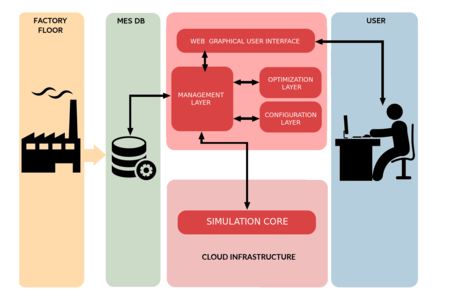

In the context of increasing the efficiency in the manufacturing operations, especially for SME, the objective of the iPlanner project is to develop a Discrete Event Simulator (or DES-based) tool, implementing it as a Finite Capacity Scheduler (or FCS), with the main aim to optimize all the manufacturing orders and processes within a factory. According to this approach, the simulator will act as a Cyber Physical Production System (CPPS), monitoring the physical resources of a factory-floor to control the complete production chain and its performance. In addition, the proposed software will be designed with the ability to process a huge amount of data related to both the state of the factory and the production processes, to learn and evolve with the experience and time, resulting in a scheduler application to minimize the impact of incidents on productivity and to optimize fabrication costs.

Project type

Prototype

Project budget

(IoT4industry funding): 90 000€

Project end date

(estimated): 31.06.2020

Partners involved

| Logo / Website | Name | Type | Country | Region |

|---|---|---|---|---|

|

Grado Zero Innovation S.r.l. (GZI) | SME | Italy | ITI – CENTRO |

| INGECONTROL | SME | Spain | ES2 - NORESTE | |

|

GRADIANT | RTO | Spain | ES1 - NOROESTE |

Vertical sector addressed

- textile

Industrial application addressed

- Logistics & supply chain

- Track & trace

- Monitoring & control

Technologies involved

- Simulation & modelling

- DES

- Finite Capacity Scheduler

- Cyber Physical Production System