Have any questions?

+44 1234 567 890

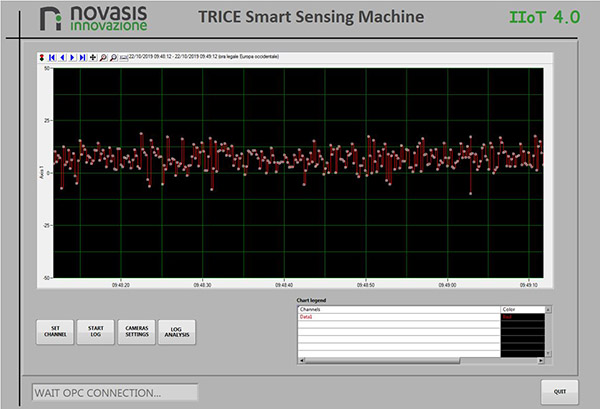

TRICE

ioT smaRt sensIng maChinE

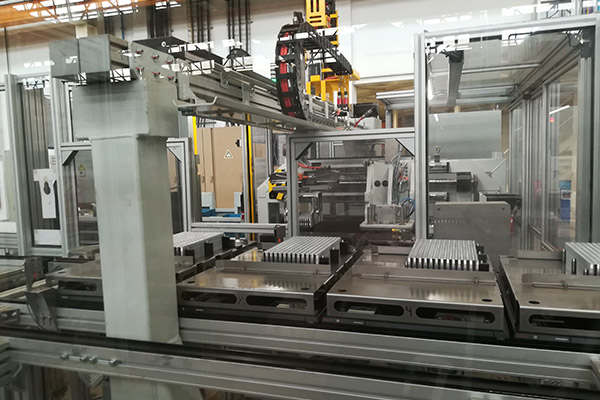

Quality and profitability certainly are the goals that need to be met in all sectors, especially in automotive and mechanical industry. Tier-1 automotive suppliers have to cope with the demand of production flexibility that requires frequently changes of production models and parts that can’t be satisfied by aged production machines without connectivity and self-learning capabilities. This applies also and in particular to the manufacturing process of air conditioning and engine cooling systems, made of many metallic and plastic parts that need to be in tolerance. Thus, the demand of a flexible IoT sensing machine with learning controllers would allow the production machines to adapt theirselves to changing environments, variable circumstances and system degradations.

TRICE project aims at providing existing production machines of the capabilities of adaptive control systems and active compensation features to fully optimize the performance of the manufacturing systems and minimize machine faults by the introduction of a smart IoT sensing machine suited to log and store in-line process parameters of a production machine, especially an aluminum fin forming machine in a heat exchanger assembly line. The optimization of the process using an automatic decision engine and the deployment of vision and optical metrology systems will improve the performance of the manufacturing system, minimizing the machine faults and increasing the quality of corrugated fins.

Project type

Demonstrator

Project budget

(IoT4industry funding): 60 000 €

Project end date

(estimated): April 2020

Partners involved

| Logo / Website | Name | Type | Country | Region |

|---|---|---|---|---|

| NOVASIS INNOVAZIONE | SME | Italy | ITC – NORD-OVEST | |

| JDEUS S.A. | Large enterprise | Portugal | PT1 - CONTINENTE |

Vertical sector addressed

- Automotive

Industrial application addressed

- Monitoring & control

Technologies involved

- Big Data & AI